How to maintain and maintain 6300 series bearings to ensure their stable operation?

In industrial production, bearings are key components of mechanical equipment, and their stable operation is crucial to the efficiency and safety of the entire production line. 6300 series bearings, as a commonly used bearing type, its maintenance and upkeep are important links that cannot be ignored.

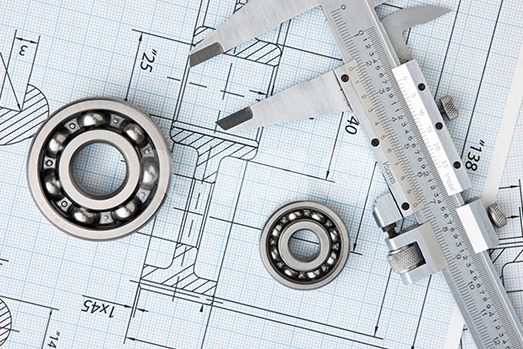

1. Understand the basic structure and characteristics of 6300 series bearings

Before performing maintenance and repair on 6300 series bearings, you first need to understand its basic structure and characteristics. The 6300 series bearings are deep groove ball bearings with the characteristics of compact structure, strong load-bearing capacity and high rotation accuracy. The inner and outer ring raceways are arc-shaped deep grooves, which can bear radial, axial and combined loads. Understanding these characteristics helps us better understand the working principle and maintenance needs of bearings.

2. Regular inspection and cleaning

Regular inspection: Regular inspection of 6300 series bearings is an important measure to ensure their stable operation. The inspection content includes the rotation flexibility of the bearing, noise conditions, temperature changes, etc. If an abnormality is found, timely measures should be taken to deal with it.

Cleaning: Keeping bearings clean is key to extending their service life. Oil, dust and other impurities around the bearing should be removed regularly to prevent them from entering the inside of the bearing and causing wear. During the cleaning process, care should be taken to use appropriate cleaning agents and tools to avoid damage to the bearings.

3. Lubrication and sealing

Lubrication: Lubrication is key to ensuring the normal operation of 6300 series bearings. The appropriate lubricant should be selected according to the working conditions of the bearing and lubricated according to the specified lubrication cycle. During the lubrication process, attention should be paid to controlling the amount of lubricant and the frequency of lubrication to avoid adverse effects on the bearings caused by too much or too little lubrication.

Seal: Good sealing can prevent external impurities from entering the inside of the bearing and protect the bearing from damage. The sealing device of the bearing should be checked regularly to see if it is intact. If it is damaged, it should be replaced in time. At the same time, during the bearing installation process, the correct installation and use of the sealing device should be ensured.

4. Installation and disassembly

Installation: When installing 6300 series bearings, ensure that the mating surfaces of the bearing seat and bearing are clean and free of damage. At the same time, appropriate installation tools and methods should be used to avoid damage to the bearings during installation. After the installation is completed, a test run inspection should be carried out to ensure that the bearing runs smoothly and has no abnormal noise.

Disassembly: When disassembling 6300 series bearings, special tools should be used to disassemble them, and avoid using hard objects such as hammers to hit the bearings. During the disassembly process, care should be taken to protect the inner and outer rings and raceways of the bearing from damage. After disassembly is complete, the bearings should be cleaned and inspected for reuse or replacement.

5. Storage and safekeeping

6300 series bearings that are not in use temporarily should be stored in a dry, ventilated, and non-corrosive gas environment. During the storage process, the storage status of the bearings should be checked regularly. If there are any abnormalities such as rust or deformation, they should be dealt with in time. At the same time, during storage and use, the bearings should be kept away from contact with sharp objects to avoid scratching the bearing surface.

By maintaining and maintaining the 6300 series bearings, we can effectively extend their service life and ensure their stable operation. In actual work, we should formulate appropriate maintenance and upkeep plans based on the working conditions and characteristics of the bearings, and strictly implement them in accordance with the plan. At the same time, we should continue to learn and master new maintenance and maintenance technologies to adapt to changing production needs.